In the joinery industry, precision, efficiency, and safety are paramount.

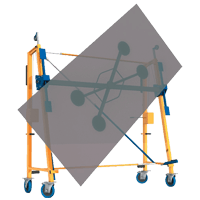

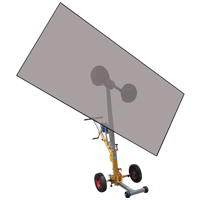

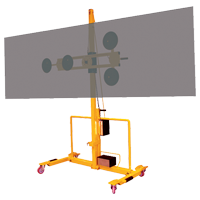

Vacuum lifters offer a versatile solution for handling a wide range of materials, enabling joinery businesses to streamline their processes and achieve higher productivity. Here are some key benefits of vacuum lifters for joineries:

Applications

Fire doors

Vacuum lifters are essential in the production of fire doors, allowing joineries to efficiently handle heavy and bulky door panels. With vacuum lifters, workers can precisely position door panels during assembly, ensuring accurate fitting and enhancing the quality of the final product.

Porous sheets

Handling porous sheets like chipboard or particleboard can be challenging due to their fragility and tendency to break. Vacuum lifters provide gentle yet secure handling of porous sheets, preventing damage and ensuring these materials remain intact throughout the manufacturing process.

MDF sheets

Medium-density fiberboard (MDF) sheets are commonly used in joinery for various applications. Vacuum lifters offer a safe and efficient way to lift and transport MDF sheets, reducing the risk of breakage or surface damage. This ensures that MDF sheets maintain their integrity and quality.

Modular Home Production

In modular home production, where precise assembly is crucial, vacuum lifters play a vital role in handling prefabricated components. From lifting wall panels to positioning cabinetry, vacuum lifters enable joineries to streamline the assembly process, resulting in faster construction times and higher-quality modular homes.